Rourkela, March 20 (IANS) Researchers from the National Institute of Technology (NIT) Rourkela have developed an Internet of Things-enabled smart device to monitor the quality of ingredients in processed food.

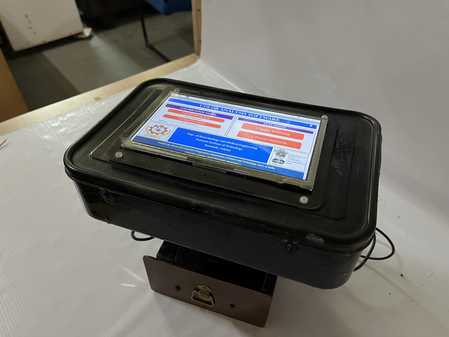

The colourimeter, developed in partnership with teams from the University of the Philippines Los Banos, Philippines, tracks colour and temperature changes in real-time, making it especially useful for studying oleo gels — fat alternatives used in processed foods.

Many processed foods rely on solid fats for texture and stability, but these often contain unhealthy trans and saturated fats, increasing the risk of cardiovascular diseases and obesity.

To address this, the food industry has been exploring oleo gels, which convert liquid oils into a gel-like form by using additives such as waxes, plant-based polymers, or other structuring agents and offer a healthier alternative.

However, they are prone to instability due to oil migration resulting from poor crystallisation, affecting food quality. Unlike traditional methods that require expensive lab equipment and skilled technicians, the new cost-effective device detects subtle colour changes in oleo gels during crystallisation.

This colourimetric approach provides an effective way to monitor oleo gel stability without requiring complex instrumentation.

The integration of IoT technology allows for remote monitoring, data logging, and automated analysis, making it suitable for both research and industrial applications.

“This smart device has the potential to improve food safety and quality control processes significantly. In addition to oleo gels, it could be used to monitor various other food products, where colour and temperature play a crucial role in determining the properties and stability of the food products,” said Prof. Kunal Pal, Biotechnology and Medical Engineering, NIT Rourkela.

“In addition to this, the device is also able to detect the freshness of several food products. For example, dairy products, bakery products, confectionery, and plant-based meat substitutes could all benefit from real-time quality assessment using this technology,” Pal added.

In the paper, published in the Journal of Food Engineering, the research team envisions that this device will not only enhance food science research but also empower food manufacturers to implement better quality control practices at a lower cost.

–IANS

rvt/